The Construction of Space Shuttle Launch Complex 39-B

A very personal and technical written and photographic history, by James MacLaren.

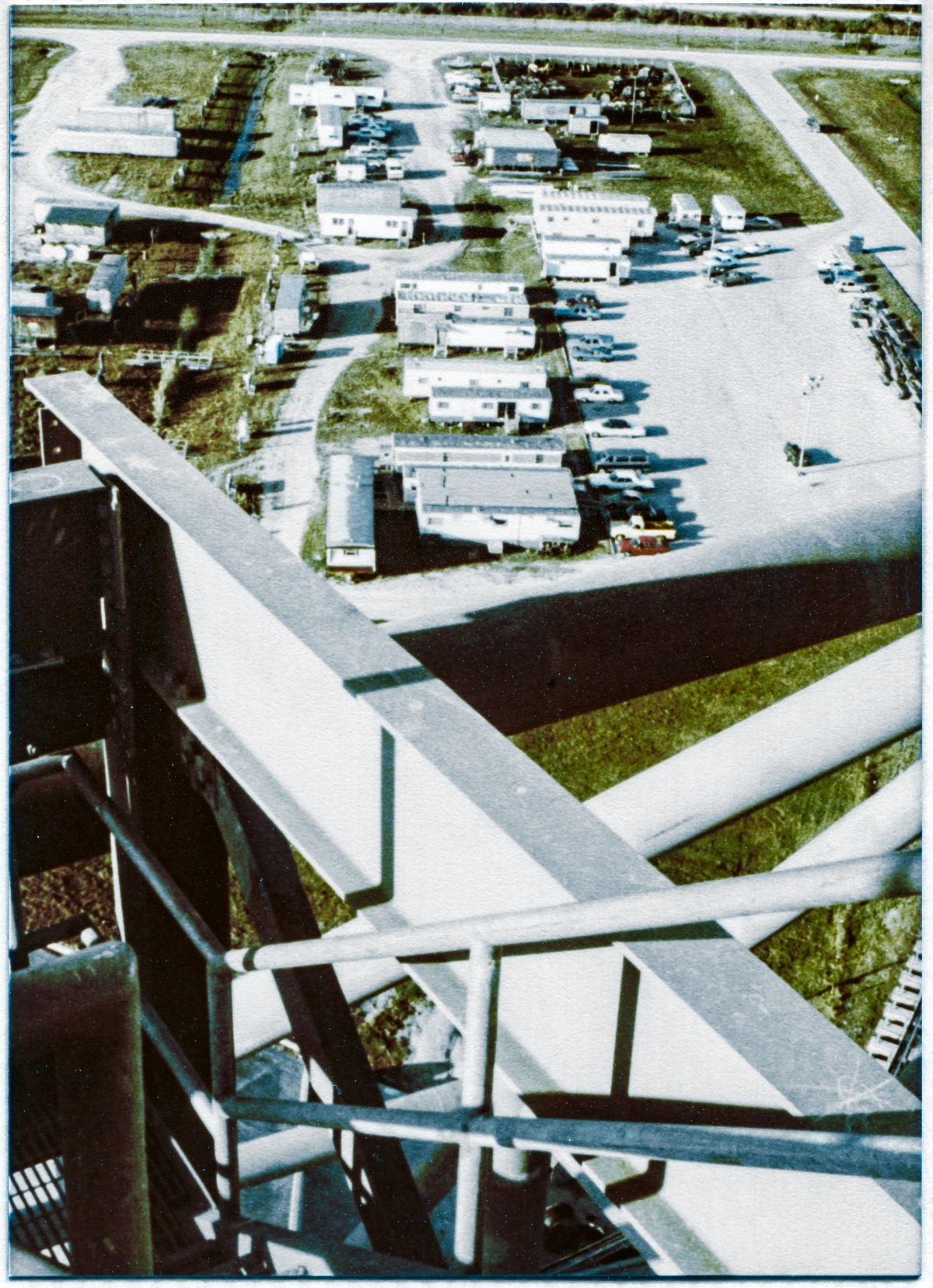

Page 27: Heavy Iron and Office Trailers.

| Pad B Stories - Table of Contents |

And from the bottom of the RSS, we go now to the top, and we turn our view a little more to the right and a bit down from where we were looking on the previous page, and here we see the whole area where the engineering and administrative end of things was done at the jobsite. Where the paper was pushed.

Where the people who didn't work, worked.

Except that they did.

The ironworkers, the pipefitters, the electricians, and all the rest of the craft labor people never grew tired of expressing their contempt for those who came and went from within the mysterious confines of these field trailers, but without that end of it, there would have been nothing for them to show up on the jobsite for in the morning, and in fact, there would have been no jobsite in the first place.

"What is it? What does it do? What are the relevant government and commercial specifications and organizational bodies having oversight for it? What's it cost? Who's going to pay for it? Which craft labor union exercises jurisdiction over it as an agreed-upon part of their job description? Where do you put it? What's it look like? What's it weigh? What's it made out of? Will it be strong enough? Light enough or heavy enough? Small enough or big enough? What sorts of material and manufacturing certifications are required to go along with it? Who's going to inspect it and sign-off on their binding agreement that it has been furnished in full compliance with all relevant manufacturing plans and specifications, and what might their jurisdiction be? What if the original item, as precisely specified in the contract, is unobtainable and you must therefore furnish an "or equal" to replace it with? What if there's a disagreement or mismatch between the governing specifications and the contract drawings? What happens if modifications work or new construction, by others, in the area where your specified item is to be installed, have rendered that area no-longer suitable for the installation, as-shown? What happens if the engineering or contract documents depict an impossible configuration in and of itself that cannot be furnished or installed, as-shown? How are you going to get your contractually-obligated material and equipment in to its final location? How are you going to fasten it in there permanently, once it's there? Who's going to inspect it and sign off on their binding agreement that it has been furnished and installed per all relevant manufacturing and installation plans and specifications, and what might their jurisdiction be? How is it all supposed to fit together? What happens if something else is in the way? What happens if somebody damages it or breaks it? How is it going to be protected and maintained once it's in place? Are you late getting your material and equipment furnished and installed, and if so, how might that be impacting other work around you which depends on your portion of the job being complete by a certain time, and how much might that be costing those affected parties, and who's fault might it be that you're late? Does the company which you work for look to remain sufficiently solvent to continue cutting paychecks for its employees until final completion of the project? Do the other companies around you look to be in an equally-sound state of financial health and well-being? What sorts of safety, environmental, and quality-control issues might come in to play with it? How shall they be dealt with, and who does the dealing and who provides oversight for it? Who shall terminate it and how might they do so? Who shall test it and how might they do so, and what if it fails the test, and what might have caused it to fail the test? Who shall validate it and how might they do so? Who will be the end-user or customer for it? How might the customer or their representatives indicate that it has been furnished and installed completely and correctly per the plans and specifications so that you can get paid for it? Who are the end-user, contracting, and engineering personnel to go to with questions or problems?"

That's the kind of stuff that went into, and came back out of, those trailers, and you don't hand-wave any of it, and you never permit anyone else around you to hand-wave their end of it, and you hold their feet to the fire even as they hold your feet to the fire, and we were the people who worked that end of it, and sometimes it was pretty straightforward, and other times it was a right bastard to do.

It was a team effort. The team was gigantic. And every member of the team was there for a reason, and every individual member of the team was necessary for the complete and correct performance of the whole team's entire alloted task.

"Build us a launch pad."

It was all very deceptive stuff that went on down in those field trailers, and very many people indeed either failed, or chose not, to recognize it.

And if the craft labor sneered in your face about it, well then, ok.

So it must be.

But it was always much better to build a rapport with people, to learn to speak their language, even when they couldn't, or wouldn't, speak yours.

Let that go.

Establish a good working relationship with everyone that you could.

Trust is a two-way street, and the traffic must be allowed to flow freely in both directions, and anything that stood as an impediment to the best possible flow of that traffic needed to be removed if at all humanly possible to do so.

Or at least with the honest ones, the honorable ones.

Not all of them were honest or honorable, and you needed to be able to swiftly ascertain who was who, or otherwise they would hurt you in their dishonorable neverending fear-driven compulsion to grab everything for themselves at the expense of all the world around them and everybody in it.

And, in my own limited experience, the odds of encountering a Bad One were much greater, because there was a significantly higher proportion of them, down in those field trailers, down where the paper was pushed.

I tended to do a lot better, in a general sense, with people who wore a hard hat all the time, as opposed to those who only had to put one on occasionally, or even never at all.

Make of that, what you will.

Ok, where are we?

We are on the RSS Roof, just off of the top of Stair Tower 4, standing on the steel-bar grating at elevation 212'-1", looking west southwest back across in the exact direction this photograph was taken from, with our eye-level point of view above and inboard of the Line A.7/5.9 corner connection of the very top of the Stair Tower 4 framing steel. A W21x57 horizontal I-beam extends away from us toward Column Line 7 to where it terminates just past the corner connection, and the last little bit of another horizontal I-beam, this one a W18x35, is seen coming in from out of frame on the left to meet and connect with the W21 at that A.7/5.9 corner. Our view is down and across the middle of the RSS Main Framing pipe member on Line 6 that runs between Line B to our left and Line A to our right, at elevation 208'-2" on-center. Two of the Main Framing pipe diagonals that slope down to Line 7 at 171'-2" from the workpoint at the top of the Main Framing pipe column at Line A-6, elevation 208'-2" (just out of frame to the right), are below the horizontal Main Framing pipe, and way down low, almost completely obscured by the intervening steel, a bit of the Column Line 7 Main Framing pipes can be seen on and near Line A, starting at elevation 171'-2" and going across and down from there.

Just as an aside, both of the wide-flange beams at the top of Stair Tower 4, despite their substantial-enough depths, would be considered quite "light" with fairly thin and narrow flanges, and thin webs, compared to their depths. A look at some of the other steel on that AISC Book page will verify that, and also, it's kind of fun sometimes to get the exact flange width and thickness, along with the total beam depth, just to bring what's shown in the photograph into even sharper understanding for what you're seeing.

Speaking for myself, coming down off of the RSS Roof using Stair 4, with the handrail pipe right next to that W21x57 where it is, it was pretty much impossible for me to pass by it without putting out my hand and resting it on the top flange, maybe gripping it across its width a little with my fingers, sliding my whole hand palm-down across the rough fine-grained surface coated in inorganic zinc paint, feeling its temperature on cold days, and again on hot sunny days, maybe pinching the near-side flange edge between my fingers, feeling the surprising hardness of the edge where the flange was squared-off, rapping my knuckles against the side of the web, and maybe on top of the the flange too, and listening to the tone and timbre of the sounds it made, and maybe even stopping there for a full minute or so, to really lay hands on it, and try to come to terms with it. Structural steel has a funny way about it where it wants you to touch it. To feel it. To attempt to physically understand it. And this beam, coming down off the RSS Roof, was one of the most well-placed pieces of somewhat-heavier steel in the whole tower for doing exactly that.

And I'm sure a lot of other people did the exact same thing, too, when coming down from the top of Stair Tower 4.

Return to 16streets.comACRONYMS LOOK-UP PAGEContact Email Link |